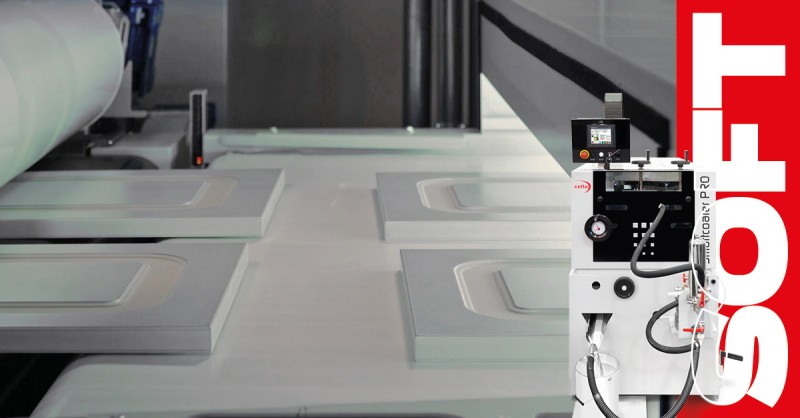

Smartcoater PRO – sustainable from all angles

As a topic which is emerging in some countries and already a mainstream issue in many others, our Smartcoater PRO from Cefla Finishing is fitted with a soft rubber application roller is promoting sustainable coating for raised panels. Eco-friendly for several reasons: less lacquer, less solvent, less waste than a spray coater system because of better transfer efficiency. Economically more sustainable: all those “less” words add up to lower costs. Sustainable for staff who are spared a number of handling operations because the coating process is accomplished in fewer steps than a spray coating solution.

Built to process all types of flat surface material, Smartcoater PRO includes key innovations and new design features, all developed to boost efficiency and improve coating quality.

A floating system with optional pneumatic control responds perfectly to surface variations on flat panels transiting through the machine. The head can be locked or unlocked depending on what the customer needs, and can also work as an emergency lift device.

Smartcoater PRO gives customers the chance to gain greater control over their process, over the lacquer applied and over productivity in general. Designed to provide maximum flexibility and top performance, Smartcoater PRO can handle different shapes, different thicknesses and uncalibrated panels, and is able to automatically adjust operating parameters so as to save time and improve coating quality.

Features

- An improved lifting system based on 4 screw jacks ensures greater stability and sturdiness for the application head

- Belt adjustments are automatic, with an optional belt-centring system

- Dose roller positioning and independent electric application device

- Recalling a specific recipe will adjust parameters accordingly without manual intervention